We supply types of boilers for the generation of steam and power required for the operation of sugar mill.

Electricity and steam are almost required in every step of raw sugar process, especially in juice extraction, clarification, evaporation and sugar drying, good quality steam takes a crucial role. Thus selection of steam boilers becomes very important for sugar plant.

Bagasse, nearly 30% fiber contained in sugar cane, is produced during the processing of sugarcane, is burned as fuel for the generation of steam and power required for the operation of sugar mill. In fact, most cane sugar factories have been designed to be energy self-sufficient, with sugar as the primary product and bagasse as the primary fuel.

A bagasse-fired cogeneration system, made of steam boilers and steam driven turbo-alternators, provides all the steam and electricity needed to run the cane mills and factory, leaving little surplus bagasse. The bagasse is fired in the boiler for producing steam at high pressure, which is extracted through various single high capacity turbines and used in the process.

ZBG Group, a leading boiler manufacturer and supplier, can supply sugar mills with high quality steam boilers. Bagasse fired boilers, coal steam boilers, bagasse fired CFB boilers, or whatever, our skilled engineers are always ready to create a solution that is perfectly tailored to your specific requirements and processes.

The Boiler House

The boiler house - a basic overview of a steam system -

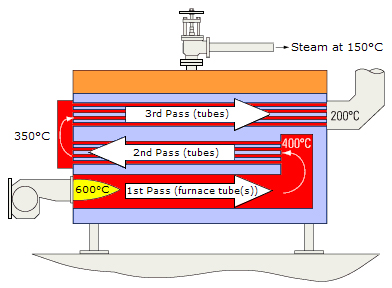

The boiler is the heart of the steam system. The typical modern packaged boiler is powered by a burner which sends heat into the boiler tubes.

The hot gases from the burner pass backwards and forwards up to 3 times through a series of tubes to gain the maximum transfer of heat through the tube surfaces to the surrounding boiler water. Once the water reaches saturation temperature (the temperature at which it will boil at that pressure) bubbles of steam are produced, which rise to the water surface and burst. The steam is released into the space above, ready to enter the steam system. The stop or crown Valve isolates the boiler and its steam pressure from the process or plant.

If steam is pressurised, it will occupy less space. Steam boilers are usually operated under pressure, so that more steam can be produced by a smaller boiler and transferred to the point of use using small bore pipework. When required, the steam pressure is reduced at the point of use.

As long as the amount of steam being produced in the boiler is as great as that leaving the boiler, the boiler will remain pressurised. The burner will operate to maintain the correct pressure. This also maintains the correct steam temperature, because the pressure and temperature of saturated steam are directly related.

The boiler has a number of fittings and controls to ensure that it operates safely, economically, efficiently and at a consistent pressure.

Typical Smoke Tube Shell Boiler

FEEDWATER

The quality of water which is supplied into the boiler is important. It must be at the correct temperature, usually around 80°C, to avoid thermal shock to the boiler, and to keep it operating efficiently. It must also be of the correct quality to avoid damage to the boiler. The image below shows a sophisticated feedtank system where the water is being heated by steam injection.

Ordinary untreated potable water is not entirely suitable for boilers and can quickly cause them to foam and scale up. The boiler would become less efficient and the steam would become dirty and wet. The life of the boiler would also be reduced.

The water must therefore be treated with chemicals to reduce the impurities it contains. Both feedwater treatment and heating take place in the feedtank, which is usually situated high above the boiler. The feedpump will add water to the boiler when required. Heating the water in the feedtank also reduces the amount of dissolved oxygen in it. This is important, as oxygenated water is corrosive.

BLOWDOWN

Chemical dosing of the boiler feedwater will lead to the presence of suspended solids in the boiler. These will inevitably collect in the bottom of the boiler in the form of sludge, and are removed by a process known as bottom blowdown. This can be done manually - the boiler attendant will use a key to open a blowdown Valve for a set period of time, usually twice a day.

Other impurities remain in the boiler water after treatment in the form of dissolved solids. Their concentration will increase as the boiler produces steam and consequently the boiler needs to be regularly purged of some of its contents to reduce the concentration. This is called control of total dissolved solids (TDS control). This process can be carried out by an automatic system which uses either a probe inside the boiler, or a small sensor chamber containing a sample of boiler water, to measure the TDS level in the boiler. Once the TDS level reaches a set point, a controller signals the blowdown Valve to open for a set period of time. The lost water is replaced by feedwater with a lower TDS concentration, consequently the overall boiler TDS is reduced.

LEVEL CONTROL

If the water level inside the boiler were not carefully controlled, the consequences could be catastrophic. If the water level drops too low and the boiler tubes are exposed, the boiler tubes could overheat and fail, causing an explosion. If the water level becomes too high, water could enter the steam system and upset the process.

For this reason, automatic level controls are used. To comply with legislation, level control systems also incorporate alarm functions which will operate to shut down the boiler and alert attention if there is a problem with the water level. A common method of level control is to use probes which sense the level of water in the boiler. At a certain level, a controller will send a signal to the feedpump which will operate to restore the water level, switching off when a predetermined level is reached. The probe will incorporate levels at which the pump is switched on and off, and at which low or high level alarms are activated. Alternative systems use floats.

It is a legal requirement in most countries to have two independent low level alarm systems.

The flow of steam to the plant

When steam condenses, its volume is dramatically reduced, which results in a localised reduction in pressure. This pressure drop through the system creates the flow of steam through the pipes.

The steam generated in the boiler must be conveyed through the pipework to the point where its heat energy is required. Initially there will be one or more main pipes or steam mains which carry steam from the boiler in the general direction of the steam using plant. Smaller branch pipes can then distribute the steam to the individual pieces of equipment.

Steam at high pressure occupies a lower volume than at atmospheric pressure. The higher the pressure, the smaller the bore of pipework required for distribution of a given mass of steam.

STEAM QUALITY

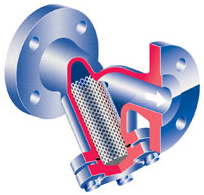

It is important to ensure that the steam leaving the boiler is delivered to the process in the right condition. To achieve this the pipework which carries the steam around the plant normally incorporates strainers, separators and steam traps.

A strainer is a form of sieve in the pipeline. It contains a mesh through which the steam must pass. Any passing debris will be retained by the mesh. A strainer should regularly be cleaned to avoid blockage. Debris should be removed from the steam flow because it can be very damaging to plant, and may also contaminate the final product.

Typical Y-Type strainer

The steam should be as dry as possible to ensure it is carrying heat effectively. A separator is a body in the pipeline which contains a series of plates or baffles which interrupt the path of the steam. The steam hits the plates, and any drops of moisture in the steam collect on them, before draining from the bottom of the separator.

Steam passes from the boiler into the steam mains. Initially the pipework is cold and heat is transferred to it from the steam. The air surrounding the pipes is also cooler than the steam, so the pipework will begin to lose heat to the air. Insulation fitted around the pipe will reduce this heat loss considerably.

When steam from the distribution system enters the steam using equipment the steam will again give up energy by: a) warming up the equipment and b) continuing to transfer heat to the process. As steam loses heat, it turns back into water. Inevitably the steam begins to do this as soon as it leaves the boiler. The water which forms is known as condensate, which tends to run to the bottom of the pipe and is carried along with the steam flow. This must be removed from the lowest points in the distribution pipework for several reasons:

- Condensate does not transmit heat effectively. A film of condensate inside plant will reduce the efficiency with which heat is transferred.

- When air dissolves into condensate, it becomes corrosive.

- Accumulated condensate can cause noisy and damaging waterhammer.

- Inadequate drainage leads to leaking joints.

A device known as a steam trap is used to release condensate from the pipework whilst preventing the steam from escaping from the system. It can do this in several ways:

- A float trap uses the difference in density between steam and condensate to operate a Valve. As condensate enters the trap, a float is raised and the float lever mechanism opens the main Valve to allow condensate to drain. When the condensate flow reduces the float falls and closes the main Valve, thus preventing the escape of steam.

- Thermodynamic traps contain a disc which opens to condensate and closes to steam.

- In bimetallic thermostatic traps, a bimetallic element uses the difference in temperature between steam and condensate to operate the main Valve.

- In balanced pressure thermostatic traps, a small liquid filled capsule which is sensitive to heat operates the Valve.

Once the steam has been employed in the process, the resulting condensate needs to be drained from the plant and returned to the boiler house.

PRESSURE REDUCTION

As mentioned before, steam is usually generated at high pressure, and the pressure may have to be reduced at the point of use, either because of the pressure limitations of the plant, or the temperature limitations of the process.

This is achieved using a pressure reducing Valve.

Steam at the point of use

A large variety of steam using plant exists. A few examples are described below:

- JACKETED PAN - Large steel or copper pans used in the food and other industries to boil substances - anything from prawns to jam. These large pans are surrounded by a jacket filled with steam, which acts to heat up the contents.

- AUTOCLAVE - A steam-filled chamber used for sterilisation purposes, for example medical equipment, or to carry out chemical reactions at high temperatures and pressures, for example the curing of rubber.

- HEATER BATTERY - For space heating, steam is supplied to the coils in a heater battery. The air to be heated passes over the coils.

- PROCESS TANK HEATING - A steam filled coil in a tank of liquid used to heat the contents to the desired temperature.

- VULCANISER - A large receptacle filled with steam and used to cure rubber.

- CORRUGATOR - A series of steam heated rollers used in the corrugation process in the production of cardboard.

- HEAT EXCHANGER - For heating liquids for domestic/industrial use.

CONTROL OF THE PROCESS

Any steam using plant will require some method to control the flow of steam. A constant flow of steam at the same pressure and temperature is often not what is required - a gradually increasing flow will be needed at start-up to gently warm the plant, and once the process reaches the desired temperature, the flow must be reduced.

Control Valves are used to control the flow of steam. The actuator, see Figure 1.3.6, is the device that applies the force to open or close the Valve. A sensor monitors conditions in the process, and transmits information to the controller. The controller compares the process condition with the set value and sends a corrective signal to the actuator, which adjusts the Valve setting.

A variety of control types exist:

- PNEUMATICALLY ACTUATED VALVES - Compressed air is applied to a diaphragm in the actuator to open or close the Valve.

- ELECTRICALLY ACTUATED VALVES - An electric motor actuates the Valve.

- SELF-ACTING - There is no controller as such - the sensor has a liquid fill which expands and contracts in response to a change in process temperature. This action applies force to open or close the Valve.

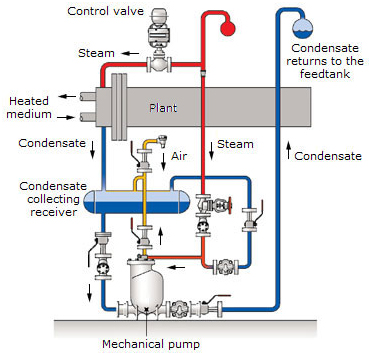

Condensate removal from plant

Often, the condensate which forms will drain easily out of the plant through a steam trap. The condensate enters the condensate drainage system. If it is contaminated, it will probably be sent to drain. If not, the valuable heat energy it contains can be retained by returning it to the boiler feedtank. This also saves on water and water treatment costs.

Sometimes a vacuum may form inside the steam using plant. This hinders condensate drainage, but proper drainage from the steam space maintains the effectiveness of the plant. The condensate may then have to be pumped out.

Mechanical (steam powered) pumps are used for this purpose. These, or electric powered pumps, are used to lift the condensate back to the boiler feedtank.

A mechanical pump, see image on the right, is shown draining an item of plant. As can be seen, the steam and condensate system represents a continuous loop. Once the condensate reaches the feedtank, it becomes available to the boiler for recycling.

Mud Drum

Sugarcane Mud Drum is the residue of the filtration of sugarcane juice. The clarification process separates the juice into a clear juice that rises to the top and goes for manufacture, and a mud that collects at the bottom

Steam Drum

Sugar Mill Steam Boiler. ... The bagasse is fired in the boiler for producing steam at high pressure, which is extracted through various single high capacity turbines and used in the process to produce Steam & Power also.

Cogeneration. Co-generation is the concept of producing two forms of energy from one fuel. ... In a conventional power plant, fuel is burnt in a boiler to generate high-pressure steam which is used to drive a turbine, which in turn drives an alternator through a steam turbine to produce electrical power.

Biomass fuel boiler and gas oil fuel boiler are widely used in sugar factory, which are environmental friendly. Biomass steam boiler is the best choice for sugar mill. The traveling grate type steam boiler that can burn both coal and biomass fuel

Headers or Manifolds

Headers are upgrade parts designed for performance applications, while exhaust manifolds are more utilitarian. ... Headers are aftermarket upgrade exhaust manifolds that use an individual steel tube for each cylinder. These tubes all connect to a collector pipe. The tubes are smooth and equal in length.

Headers are installed because they boost the rate of exhaust flow out of your engine compared to OEM stock exhaust manifolds, which are typically designed to take up as little space as possible. However, as we will see, the quality of manifold exhaust flow rate varies from Drum to Drum

Boiler Pressure Parts:-

Super Heater Coils

A superheater is a device used to convert saturated steam or wet steam into superheated steam or dry steam. Superheated steam is used in steam turbines for electricity generation, steam engines, and in processes such as steam reforming. There are three types of superheaters: radiant, convection, and separately fired. A superheater can vary in size from a few tens of feet to several hundred feet (a few metres to some hundred metres).

Providing you the best range of Stud Welded Bed Coil, Radiant Super Heater, Plain In-bed Coil, Primary & Secondary Super Heating Coil, Boiler Headers and Boiler Bank Tube with effective & timely delivery.

Primary & Secondary Super Heater coils:-

By keeping track with the market development, we are engaged in manufacturing, exporting and supplying an optimum quality Primary & Secondary Super Heating Coil. This coil is used for maintaining high temperature in heating room. Provided coil is thoroughly inspected by our skilled team of professionals to ensure its durability and quality. It is manufactured with fine quality of raw material which conforms to safety standards with the aid of sophisticated technology at our efficient manufacturing unit. Our clients can avail it from us at a reasonable price with no hassle.

Features:

- Rust proof

- Low power consumption

- Easy installation

By keeping track with the market development, we are engaged in manufacturing, exporting and supplying an optimum quality Primary & Secondary Super Heating Coil. This coil is used for maintaining high temperature in heating room. Provided coil is thoroughly inspected by our skilled team of professionals to ensure its durability and quality. It is manufactured with fine quality of raw material which conforms to safety standards with the aid of sophisticated technology at our efficient manufacturing unit. Our clients can avail it from us at a reasonable price with no hassle.

Features:

- Rust proof

- Low power consumption

- Easy installation

Plain In-bed Coil

Our firm specializes in offering an excellent range of Plain In-bed Coil that is widely used in various industries for several applications. This coil isused in economizers of different water tube boilers. Our offered coil is manufactured utilizing optimum quality raw material and advanced technology by our skilled professionals. In order to ensure quality, this range of coil is rigorously tested on various parameters. Apart from this, we provide the entire range as per the requirement of our prestigious clients.

Features:

- Precisely designed

- Easy installation

- Rust resistance

Boiler Headers

Our reputation in the market is largely attributable to our precision-designed Inbed Super Heater from our extensive collection of products. Technology used in manufacturing process is highly sophisticated and enables us to add much-needed touch of uniqueness to the entire range of heater. Widely used in situations where high temperature is needed, this heater is available at affordable market prices within the promised time frame.

Features:

- Sturdy design

- Highly durable

- Excellent performance

Boiler Bank Tube

We feel immensely pleased to offer an exclusive gamut of Boiler Bank Tube at cost effective price. Find wide application is sugar, refinery, steel plants, small and large utility/captive power plants, this tube used to connect steam and mud drums in a boiler. The offered range is meticulously tested on various quality parameters and is widely demanded in various industries. Provided range is manufactured by utilizing pristine quality raw-material and the latest technology by our skilled professionals.

Features:

Rust proof

- Ruggedness

- Ability to withstand high temperature and pressure

Shieling for Bends & Boiler Tubes from erosion:-

We are leading manufacturer and supplier of Cassette Baffles and SS Erosion Protection shields.

When flue gases come in contact with the bend of the boiler tube, the surface of the bend becomeseroded. Erosion shields are used in high temperature applications and to avoid the erosion rate inboiler tubes at the bend, the shield is used to protect the boiler tubes.